Industrial Automation Solutions

At Sirin Software, we turbocharge industries with custom automation. The contributions we make are significantly beneficial to the fields of manufacturing and logistics. Our solutions streamline workflows, reduce errors, and boost production.

Awards

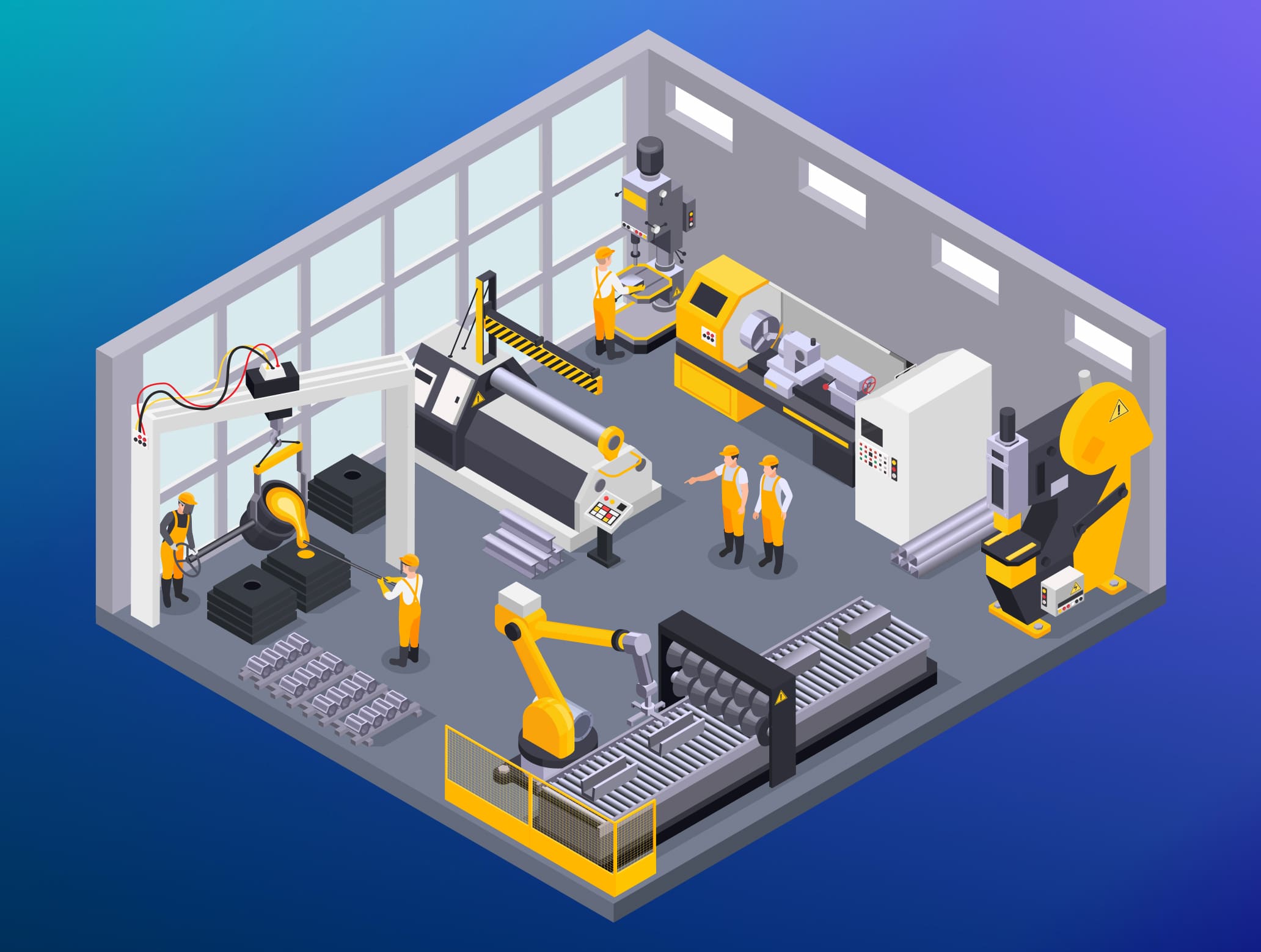

Industrial automation solutions leverage control systems like software, robots, and IT for optimized operations.

Imagine an automated car production line. Here, Programmable Logic Controllers (PLCs), specialized industrial computers, oversee each production phase.

Robotic arms assemble parts, vehicles move on conveyor belts, bodies get painted, and quality checks occur—all automatically.

Then, we have SCADA systems, collecting and analyzing real-time data from various process points. Consider a large oil refinery. SCADA monitors temperatures, pressures, and flow rates, enabling informed decisions based on live data.

Finally, Machine-to-Machine (M2M) communication plays a key role. It facilitates mechanisms interaction within a factory, adjusting processes in response to speed variations for optimal flow, and preventing bottlenecks. Industrial automation is a complex yet harmonious system of interconnected technologies.

What We Do

Intelligent Manufacturing

From PLC-controlled assembly lines to applying machine vision in food processing and factory operations with M2M solutions, our expertise is transformative

Next-Level Monitoring

SCADA systems for live data in oil refineries, RFID-based logistic digitization for cargo tracking, and AI for predictive maintenance - our capabilities redefine industry standards

Innovative Automation

Picture healthcare labs with robots for rapid sample testing, and farming revolutionized by IoT for irrigation and yield prediction. That's what we bring to the table

Benefits of Using Industrial Automation Solutions

Cost Savings

Automation, substituting human labor with automated systems, not only saves wages and benefits but also trims expenses linked to human resources. It curbs waste and minimizes downtime, driving cost savings.

Improved Quality

The precision of automated tasks leads to enhanced quality control and reduced product defects. Consistency and accuracy are the stalwarts of automation, contributing to an improved end product.

Enhanced Safety

Engaging automation for dangerous or hazardous tasks minimizes workplace accident risks and injuries. Thus, fostering a safer environment and mitigating potential hazards for human operators.

Success Stories

HMI Implementation for 3D Scanner

The Touchscreen interface improves the efficiency and accessibility of working with the 3D scanner by transferring hardware notifications, warnings, and errors from the PLC to the GUI via the PPU.

Orders System Packaging Optimization for Warehouses

The system which optimizes warehouse property accounting and facilitates orders’ packaging. It includes a Generalscan Bluetooth Barcode Scanner and mobile app for scanning barcodes of pre-listed products.

News

FAQ

1. Will automation make my employees obsolete?

No, automation often takes over repetitive tasks but doesn't make employees obsolete. Instead, it makes work easier and more efficient for your existing team, who will manage the new system.

2. How will automation integrate with my existing systems?

Most automation technology is designed with integration in mind. Sirin Software focuses on maintaining the integrity of your plant functions and ensuring a seamless integration into your existing systems.

3. Are automated systems always better or faster?

Not always. Simple techniques can be over-engineered by automation. Our team ensures only necessary automation is applied, considering system effectiveness, team readiness, and integration with existing systems. This provides higher efficiency and faster production without unnecessary complexities.

4. Why should I consider automation for my business?

Automation can enhance production efficiency by accelerating processes, reducing errors, and increasing flexibility. It also lets you gather critical data efficiently, keeping you competitive. Our experts can help eliminate the harmful effects of the human factor with unique solutions.