HMI and GUI: Are They Substitutes for One Another?

HMI (Human Machine Interface) and GUI (Graphical User Interface) are often considered synonyms. However, in practice, they can coexist in the same project and be implemented separately. Below we invite you to learn about the key differences between the HMI and GUI.

GUI AND HMI: THE MEANING OF THESE CONCEPTS

So, let’s start with the definitions.

A GUI (Graphical User Interface) is a type of visual interface in which all controls are represented in the form of buttons, pictures, input fields, and other graphic elements. In this case, the user interacts with the device and, in fact, the interface itself, not by inputting textual commands (as is the case, for example, with the command line interface, CLI) but with input devices (mouse, trackball, etc.). Most modern desktop and mobile applications embody a GUI, as do the operating systems themselves.

Here are three notable examples of great GUIs.

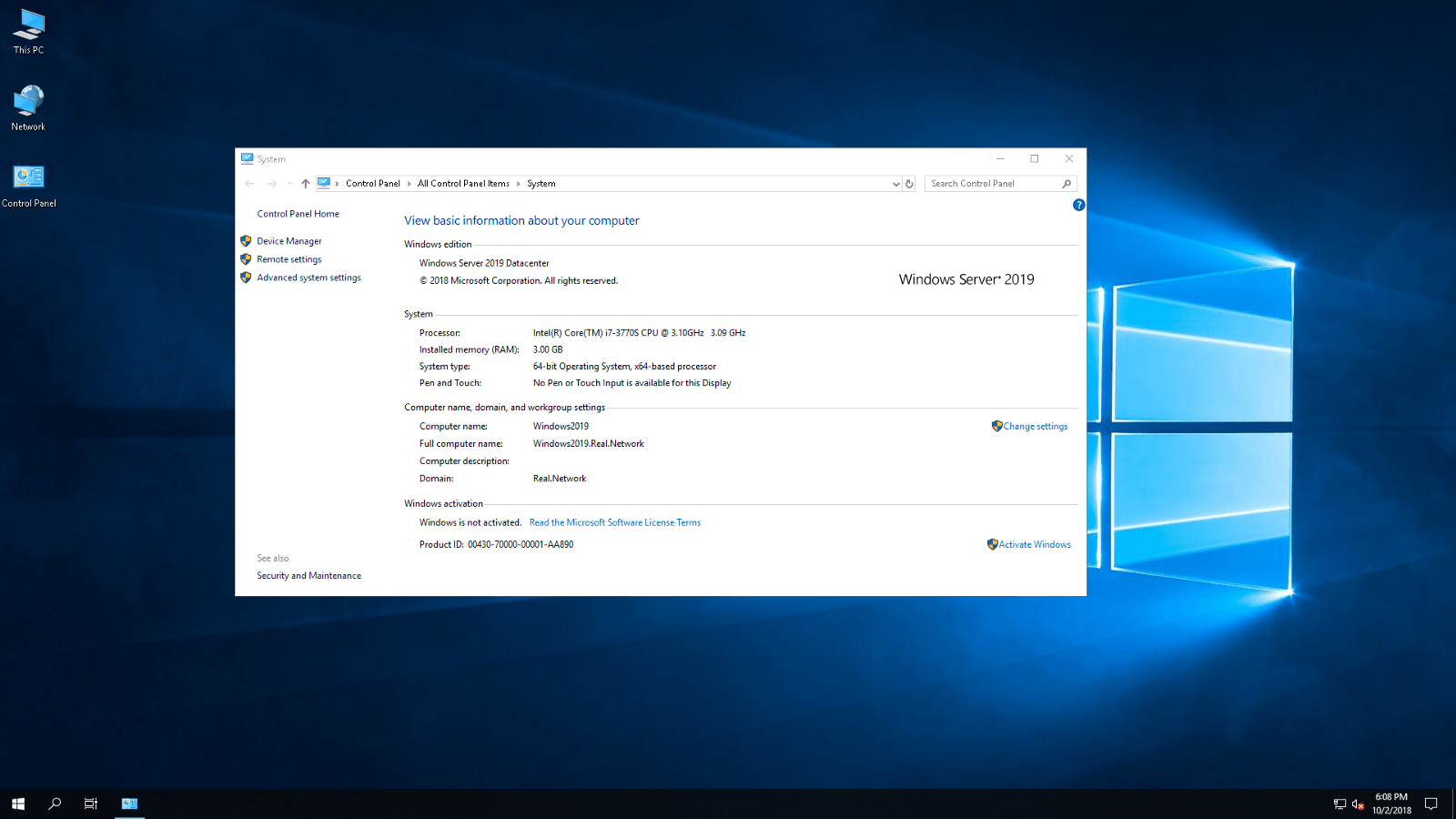

1. Microsoft Windows 10 – Metro or Modern UI

The basic principles of appearance were largely borrowed from transport node information systems. Inscriptions and graphic elements within these systems have quite specific requirements: very high readability of information, the absence of distracting elements, and a clear and precise presentation. Ideally, a person should quickly perceive the information provided and receive clear and unambiguous indications of the necessary actions. But not only that: the appearance should be pleasant, neat and leave a good impression on the user.

2. ISC DHCP Server

In our opinion, this looks extremely intuitive, even for a novice user, despite the complexity of the tasks it solves.

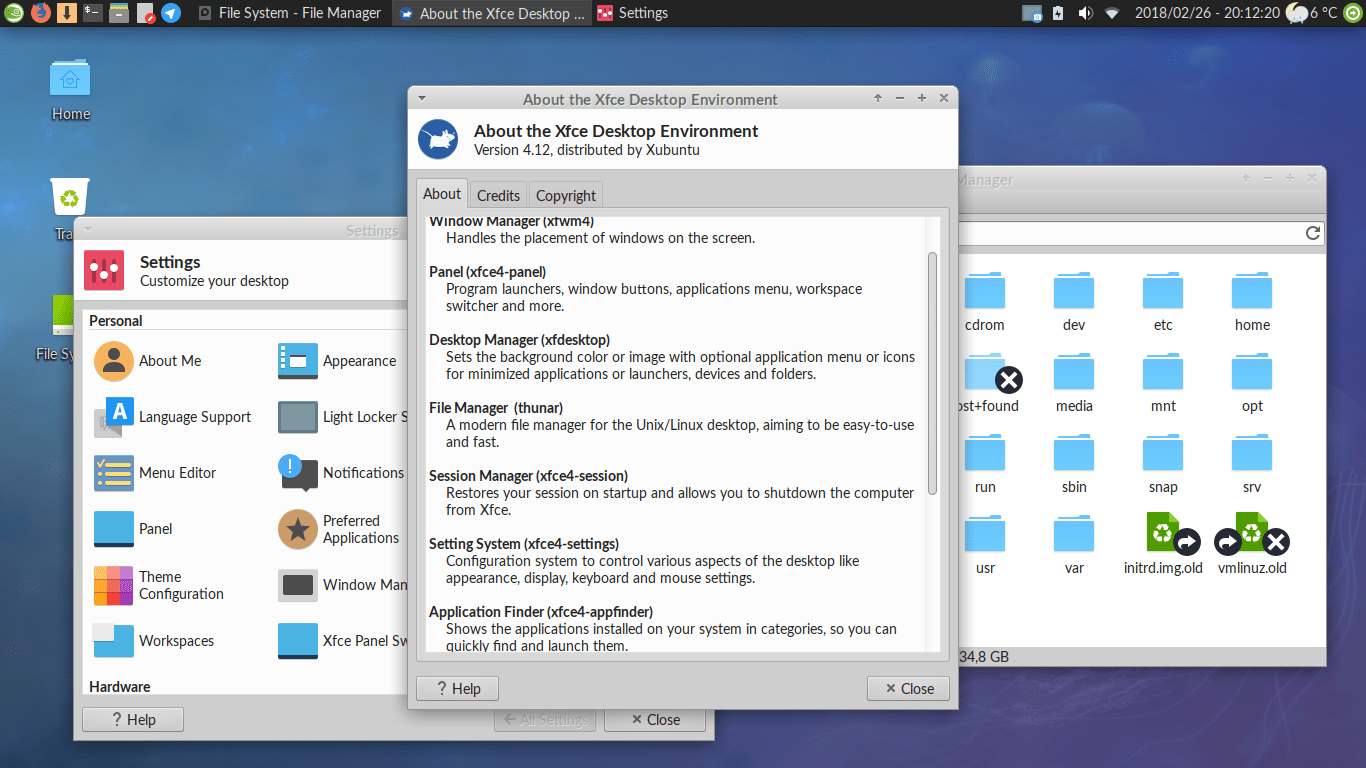

3. XFCE

And finally, the third example is XFCE, which is a graphical lightweight user interface for the Linux operating systems family.

In turn, the HMI (Human Machine Interface) is a set of technical tools designed to implement the interaction between a user and technical equipment with the purpose of its management, control, and setting of operating parameters. The interaction is usually implemented either through physical controls (buttons, switches, LEDs, screens, etc.) or control panels. All sorts of HMI implementations can be found in industrial, medical, telecommunication, aerospace, and other narrowly specialized equipment.

Actually, modern control systems flexibly combine elements of both interfaces to make management of devices and units maximally simple and comfortable. Examples are automated workspaces, mobile computers based on industrial microcontrollers with a SCADA system deployed that allows displaying various HMI elements graphically (e.g., through a GUI). Depending on the settings and the machine the panel is connected to, the exact set of controls may vary or even change dynamically.

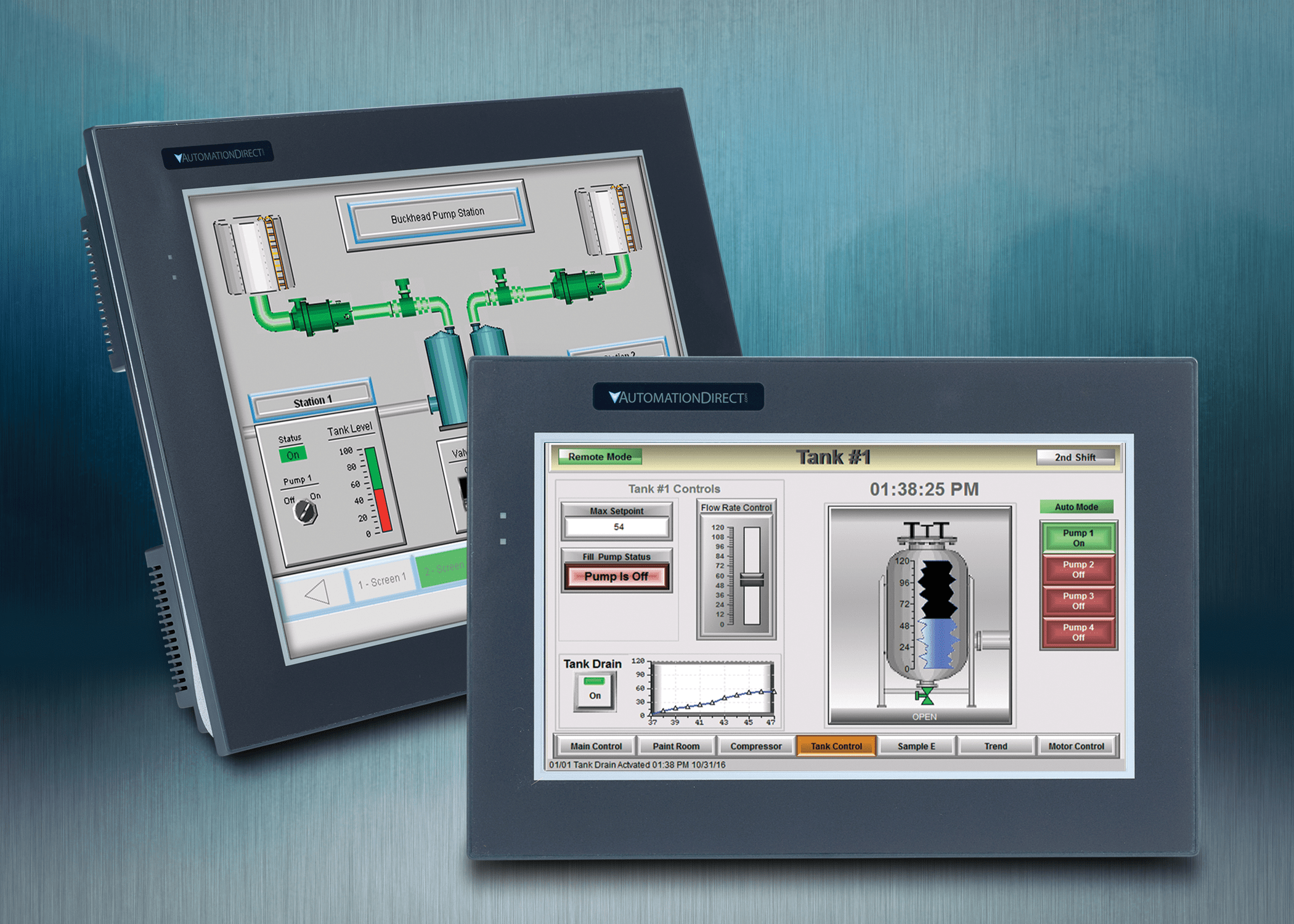

Here are examples of great modern HMI solutions.

C-more HMI

This HMI panel deserves special attention, providing the user with a graphical interface in conjunction with a functional touchpad. This device is able to completely replace almost any peripheral device and becomes part of your automation system. This is a great budget option for smaller businesses.

The second, no less successful example of a modern HMI is a Siemens SIMATIC HMI Basic Panel. This family includes models ideal both for operators with a stationary workplace and those who constantly move around the production facility.

As a third example, we bring to your attention the Nextion panel, which is often used in conjunction with Arduino microcontrollers and Raspberry Pi minicomputers.

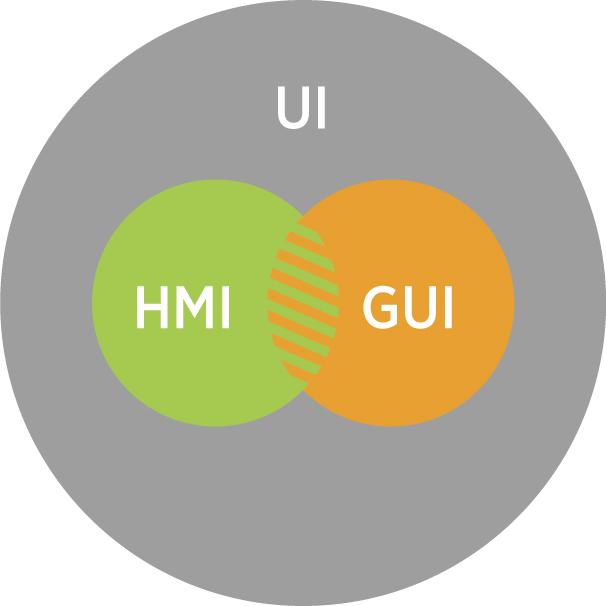

WHAT IS THE DIFFERENCE BETWEEN HMI AND GUI?

After reviewing the definitions of the HMI and GUI , let us systematize their fundamental differences.

- The scope of application. As stated above, the most common example of a GUI is a regular PC. Interfaces of modern operating systems are extremely intuitive and almost never require special training. With the HMI things are different. The main scope of its implementation is industrial automation devices (all kinds of machines, control systems, etc.), medical equipment (these range from complex life-support systems to the most common pressure measuring devices), aerospace hardware (in fact, every device on board an aircraft, with the exception of the onboard computer, has elements of HMI interfaces), etc. These require knowledge of the operated machine, its controls, preemptive training, and certification. Modern tractors, excavators, cranes – all of these machines are also controlled via an HMI. In fact, HMI elements are physical controls of a particular device (for instance, in the case of a crane, these are the hand manipulation controls, in the case of a hand-held tonometer, this is the pump that siphons air into the sleeve, and so on).

- Principles of control. The next distinguishing characteristic is the principle of control. The main task of the HMI is to provide control over the operation of the specific machine. Usually, they are placed on the housing – these are all kinds of physical switches, meters, gauges, knobs, buttons, etc. Habitual HMI controls are operated manually. As for the graphical interface, its elements are regular pictures on the display. GUI controls are manipulated by a cursor controlled by coordinating devices such as a mouse, trackball, trackpad, joystick, sensor panel, etc.

- HMI and feedback of its elements to user actions are physical. Most advanced modern HMI devices are universal control panels – specialized microprocessor-based gadgets that come with a pre-installed firmware and execution environment for user HMI projects. In addition to these devices, our firmware development service offers tailored solutions to enhance and customize your experience. Feedback is provided through separate controls – lamps, LEDs, screens, dials, etc. To implement the GUI, ordinary monitors are used. To provide feedback and simulate reaction to user input, some elements are redrawn and some new ones are displayed.

- HMI elements are constructed on industrial design/ergonomics guidelines. In turn, a GUI is created in accordance with the specific platform guidelines and customary coordinating devices.

- Basic operation principles. In essence, both kinds of interfaces work on the basis of sending some kinds of signals to executive devices. HMI controls do this by switching the flow of electricity, electrically or mechanically. In turn, GUI controls start the execution of software modules/applications.

IMPLEMENTING HMI AND GUI IN ONE PROJECT

To prove the point further, we wish to bring to your attention one of our projects in which both an HMI and a GUI coexist synergistically.

Generally speaking, our team was tasked with creating a GUI for a 3D scanner that would identify objects using special algorithms and optical elements with the highest possible accuracy. As a result, we created not just a graphical interface, but a full-fledged sensor-control based dashboard, which was integrated with the main device. Following this achievement, we also focused on industrial automation solutions development, further enhancing our capabilities. We successfully coped with the task, exceeding all the customer’s expectations.

SUMMARY

To conclude, we must assert that the GUI and HMI are two not opposing but complementary technologies that work together very well. After all, all the basic controls in a computer, such as the power button, belong to the HMI world. In turn, a screen with a GUI can be a part of a machine’s controls, or in the case of HMI panels, a GUI is used to represent the physical controls.

It does not matter how difficult your device is to manage – we will find the best approach to any product, to expand its current functionality and make it accessible to every potential user. Contact us today – and we will make any task feasible!