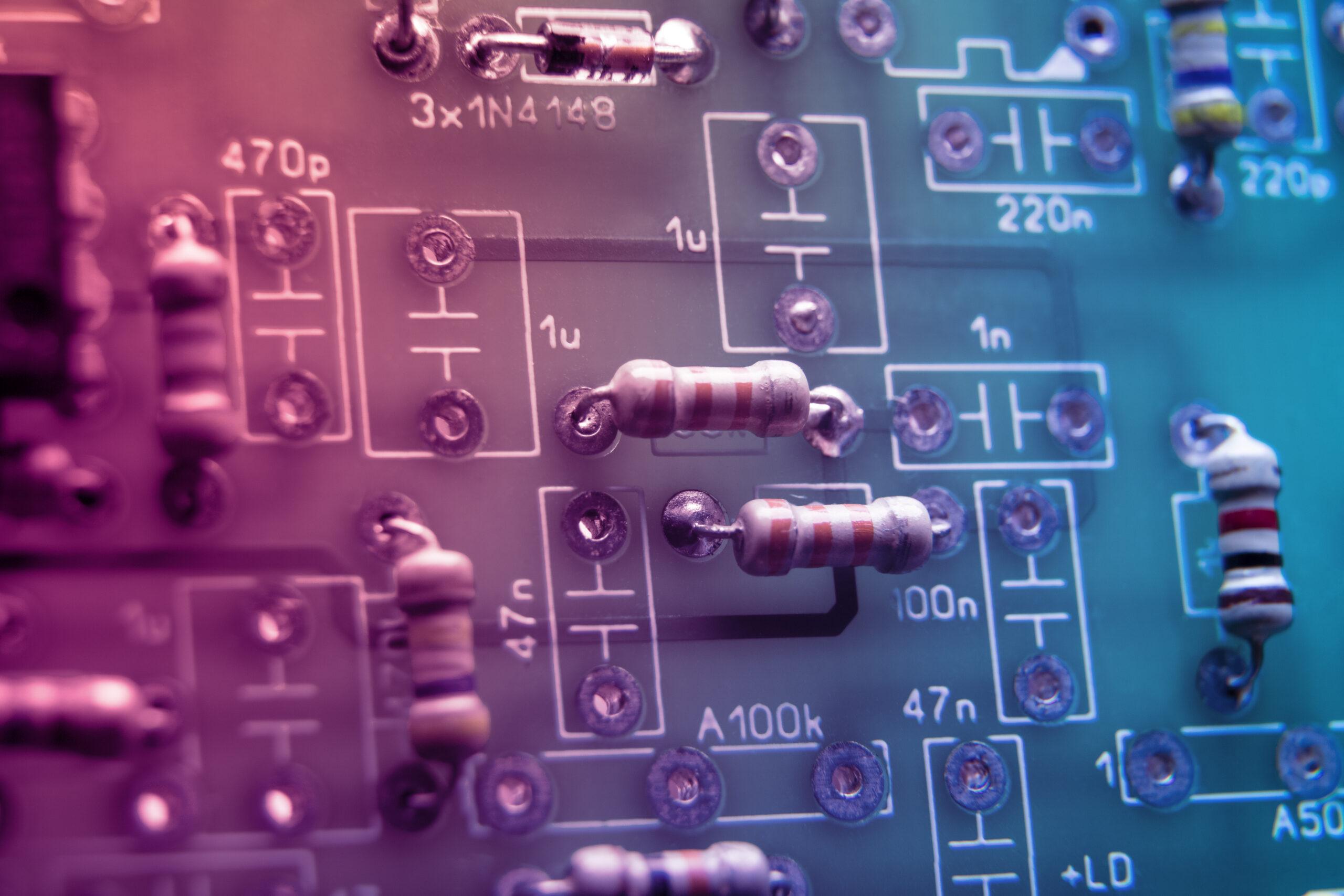

Power Electronics Design Services

Our skilled professionals deliver custom, high-performance power electronics solutions. We specialize in power conversion, motor drives, and green energy, using cutting-edge tech for seamless integration and peak performance. What sets us apart: unrivaled customer support, agile methods, and exceeding client expectations.

Awards

We’re experts at power electronics development services that turbocharge a range of industries. Transport firms, for one, capitalize on our advanced designs to optimize their fleet energy management, making operations greener and more cost-effective. Our specialized services enable healthcare providers to power essential medical devices seamlessly, promoting patient care continuity. We proficiently maneuver complex tools and methodologies, such as power factor correction and PWM controllers, to forge tailor-made solutions aligned with your business objectives.

Battery Management Systems

With expertise in Li-ion and Li-poly batteries, we ensure optimal charge, discharge, and safety with our custom management systems.

Motor Drive Design

Specializing in BLDC, PMSM, and stepper motor control systems, we use advanced algorithms like FOC and sensorless control for peak performance.

Custom Power Modules

We create power modules customized for specific applications, combining power components, control circuits, and thermal solutions.

Power Conversion Systems

We create efficient AC/DC, DC/DC, and DC/AC converters, ideal for renewable energy systems, EV chargers, and industrial automation.

Electric Vehicle Charger Design

Compliant with IEC 61851, SAE J1772, and CCS, our EV chargers ensure safe and efficient charging for AC Level 1 & 2 and DC fast chargers.

Renewable Energy Systems

We build power systems for renewable energy applications, maximizing grid integration with solar inverters, wind converters, and energy storage systems.

Our Power Electronics Design Services

Cooperation Scenarios

Industries We Work With

Why Choose Sirin Software?

Technologies We Use

| Hardware Design and PCB Layout | Altium Designer Cadence OrCAD KiCad Eagle |

| Firmware and Software Development | C/C++ Python VHDL Verilog |

| Control Systems | LabVIEW PLC (Programmable Logic Controllers) PID Controllers Embedded Systems |

| Simulation and Modeling | MATLAB/Simulink PLECS LTspice PSIM |

| Testing and Validation | Oscilloscopes Signal Generators Power Analyzers Thermal Imaging Cameras |

FAQ

What components contribute to energy efficiency in your designs?

A high-efficiency MOSFETs and IGBTs for switching applications, low ESR capacitors for filtering, and high-efficiency transformers for voltage regulation. These components are selected based on their ability to minimize losses and improve overall system efficiency.

How do you enhance the reliability of a power electronics system?

Our power electronics design service adheres to IPC standards for PCB design and uses MIL-SPEC components for high-reliability applications. Our designs undergo HALT (Highly Accelerated Life Testing) and HASS (Highly Accelerated Stress Screening) to test their long-term reliability.

How do you manage thermal issues and electromagnetic interference (EMI)?

For thermal management, we use Computational Fluid Dynamics (CFD) simulations to optimize heat sink designs and thermal interface materials. EMI is mitigated through careful PCB layout, shielding, and the use of EMI filters compliant with CISPR standards.

How do you work on safety in your designs?

We prioritize safety in our power electronics design process by incorporating features like over-voltage, over-current, and thermal protection circuits. We also adhere to relevant safety standards such as IEC 62368-1 to make sure that the end product is both reliable and secure for use.

What types of batteries do you value in your power electronics engineering services?

Our designs support a wide range of battery chemistries, including Lithium-ion, Nickel-Metal Hydride (NiMH), and Lead-Acid. We implement Battery Management Systems (BMS) for optimal charging and discharging cycles.