Molecular Beverage Printer: Telemetry, QML UI & Advanced Algorithm Upgrades

About the Client

Company’s Request

Technology Set

Communication Protocol | |

DBus | An inter-process communication (IPC) system, allowing multiple, concurrently running computer programs to communicate with one another. Implemented for communication between different components of the system, synchronized operations, and data sharing. |

Operating System | |

FreeRTOS | A real-time operating system kernel for embedded devices. Given the need for timely and precise operations in beverage dispensing machines, FreeRTOS was chosen for its efficiency, compactness, and real-time capabilities. |

Frameworks & Libraries | |

Qt | A free and open-source widget toolkit for creating graphical user interfaces. Qt was instrumental in building the user interface of the beverage dispensing machines, offering a responsive and visually appealing experience. |

QML | A user interface markup language, QML is used for designing application user interfaces where touch operation, fluid animations, and user experience are central. It was employed to make the UI not only functional but also user-friendly and engaging. |

Programming Languages | |

C | A foundational programming language that offers low-level access to memory and system processes. In this project, C was used for performance-critical components and direct system interactions. |

C++ | An extension of C, C++ offers object-oriented features and is known for its performance and flexibility. Has been used in developing complex functionalities and integration with the Qt framework. |

Solution

Our collaboration with Cana was marked by technical prowess and innovative vision. Together, we joined forces to enhance the capabilities of Cana’s machines, with Sirin Software’s dedicated team playing a pivotal role in this endeavor.

A cornerstone of our solution was the telemetry subsystem, meticulously crafted using C++, Qt, and QDBus. This system became a vital component, continuously monitoring the device and delivering real-time alerts for events and errors. This proactive monitoring ensured the equipment ran without any issues, avoiding possible interruptions in service.

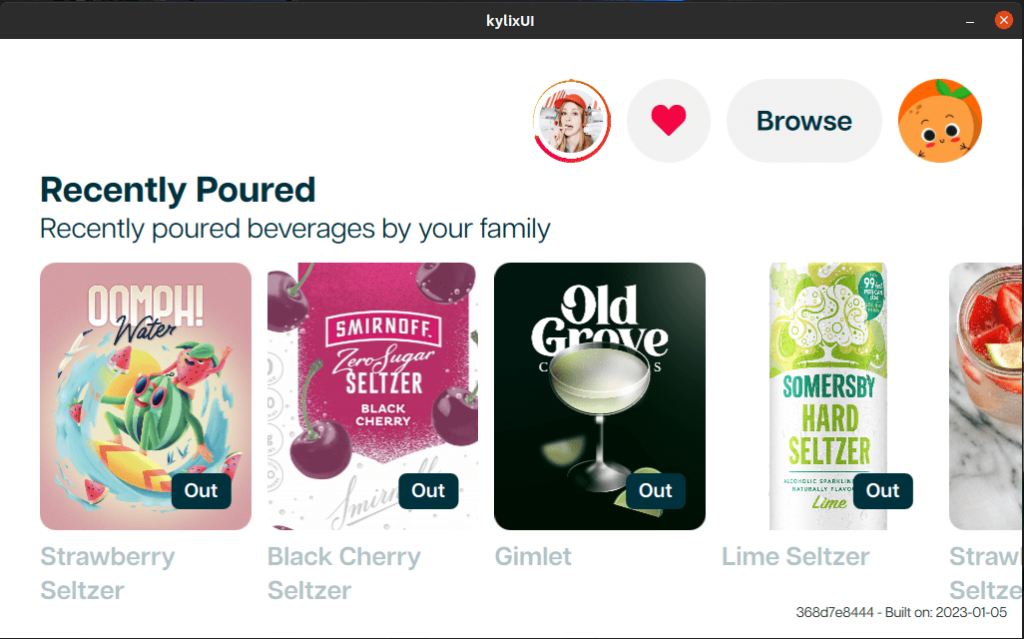

The user interface, a critical touchpoint for Cana’s customers, underwent a transformative overhaul. Our developers created a visually appealing, vertically scrollable collection of media by utilizing QML’s dynamic features. The system’s pour control was intentionally integrated with this improvement to give users a rich and engaging beverage-choosing experience.

Beyond those obvious improvements, our team looked closely at the system’s inner workings. For improved efficiency, stability, and information delivery, the QML UI was optimized. Backend interfaces were also improved to prepare the system for upgrades and additional functions in the future. We also created a hidden Debug UI, that offers a diagnostic view into the internal functioning of the system, required for tuning and diagnostics.

Value Delivered